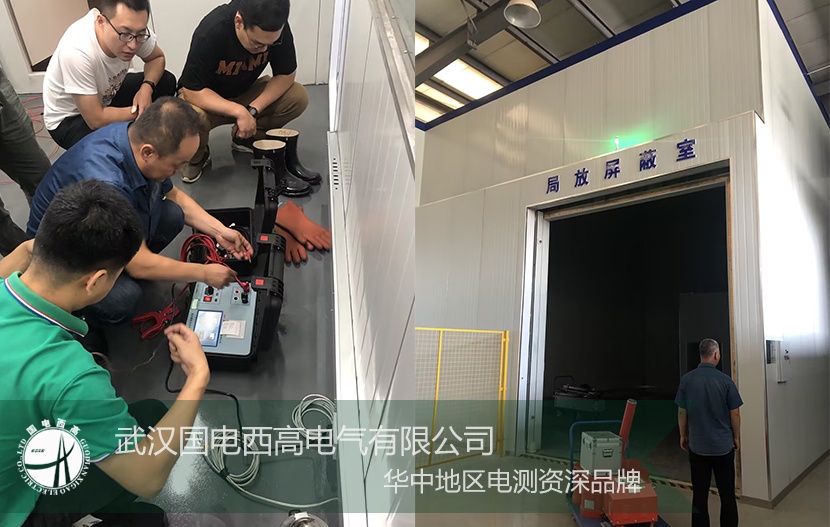

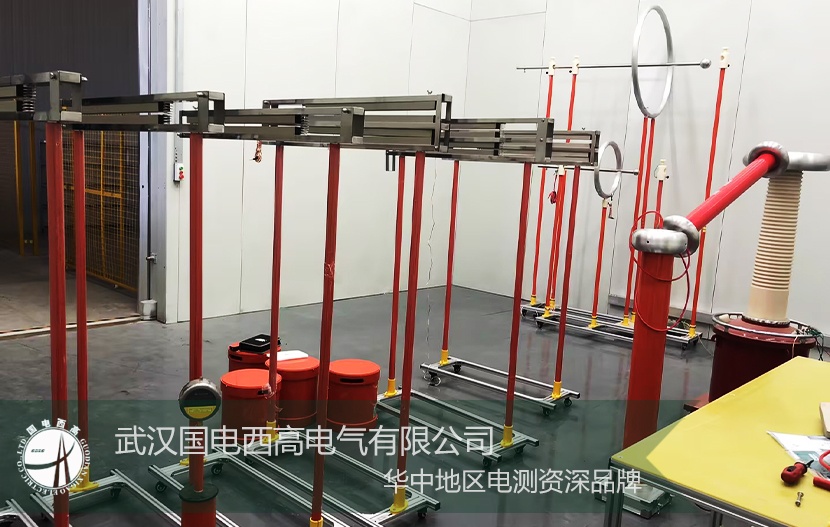

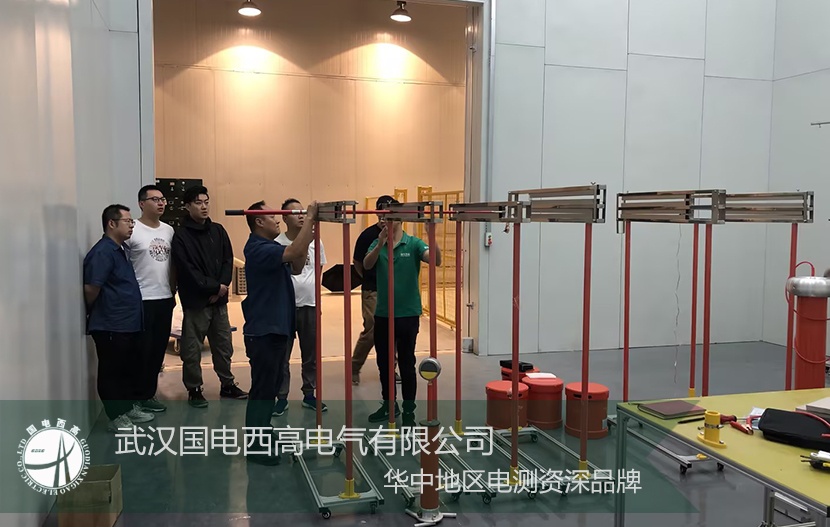

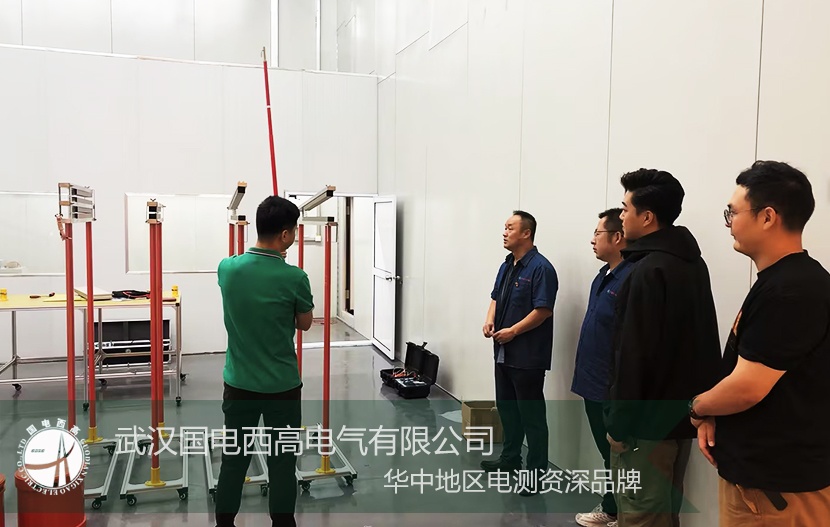

Our technical staff recently went to a metrological quality inspection and testing institute to debug equipment and demonstrated the GDYD-2020D intelligent withstand voltage test device, GDJ-150/3 insulated rod test electrode device, and GDT-150/3 to relevant professionals. Test methods and operating procedures for products such as the insulation ladder test electrode device and the GDTF-108KVA-108KV variable frequency series resonance test device.

As a company dedicated to the production and research and development of high-voltage equipment, HV Hipot continues to pursue excellent quality and technological innovation. The purpose of this equipment debugging is to ensure that these high-voltage test devices can operate normally in various practical application scenarios and comply with standards and requirements.

HV Hipot’s technical staff demonstrated the functions and operating procedures of each equipment during the debugging process. They explained in detail how to correctly set parameters, use the equipment and perform experiments, and demonstrated the stability and accuracy of the equipment in different test environments. Relevant professionals from a metrology, quality inspection and testing institute actively participated and spoke highly of HV Hipot’s equipment. They expressed their appreciation for the performance and ease of operation of these advanced equipment and said they would give full play to their value in practical applications to improve detection efficiency and accuracy.

Over the past few years, HV Hipot has always adhered to the business philosophy of “quality and service go hand in hand”. While constantly upgrading product performance, it has also been accelerating the pace of improving the service system, striving to achieve higher efficiency, better quality, and greater To fully meet the needs of customers and repay the support and trust of our customers!

Post time: Sep-15-2023